Before we discuss all of the considerations necessary to design a successful high-speed bulk bag filling line, let's first agree on what "high-speed" means!

If you are currently filling four bulk totes per hour, 10 bags per hour may seem to be high-speed. After all, that's a 250% rate increase!

If you're filling 10 bags every hour, an automated bulk bag filling system that produces 15 - 20 FIBCs in the same time it takes you to fill 10 is a big deal.

However, at least for the purpose of this article, we're going to define high-speed bulk bag filling as producing 30 or more filled bulk bags per hour.

Yes, that's a lot, but it can be done consistently, with excellent weighing accuracy and such a rate can be achieved while producing stable - safe - bulk bags.

Sequence of Events

What happens when filling bags at a total rate of over 30 tons - 60,000 lb - per hour? Well, exactly the same things happen as when filling 3 bags per hour, except they happen in a much shorter period of time.

Here is the timing chart for a bulk bag filling system designed to achieve a rate of 30 bags per hour:

| Task |

Task Duration (seconds) |

| Bag rigging |

30 |

| System start |

5 |

| Bag Fill |

55 |

| Final Densification |

15 |

| Remove filled bag |

15 |

| |

120 |

| |

|

Those are the same five tasks that are required to fill virtually any bulk bag at any rate. However, as you can see and as we predicted above, the duration of each task is very short if we want to achieve a total cycle time of only 120 seconds!

High Speed Bulk Bag Filling - Critical System Considerations

Bulk Bag Design

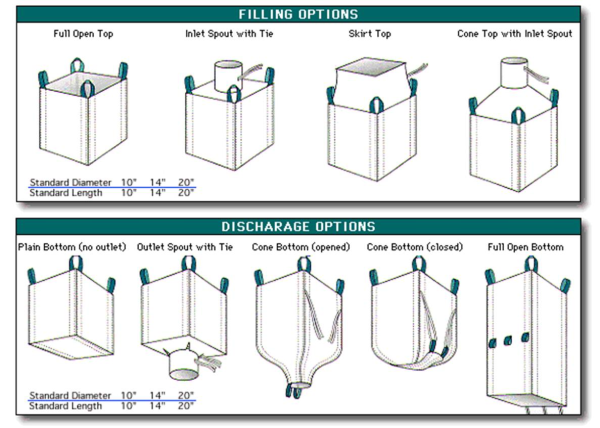

The design of your bulk bag must support the overall system required to achieve a high speed bagging rate.

For example, is the design of the loops compatible with the equipment such that they will be easily released and not hang up when the bag is automatically removed from the filling machine?

Is the diameter of the inlet spout big enough to accommodate the filling machine fill head - that has been designed to achieve the instantaneous flow rate necessary to fill the bag in the required time?

Bulk Solid Handling System

The system that moves or conveys the dry bulk solid powder, flake, granules, pellets, etc. to the bulk bag filling system must be sized to maintain the gross throughput of the system. In the case of 30 - one ton bags per hour, that is 60,000 lb per hour.

Instantaneous Bulk Solid Flow Rate

Ensuring that the bulk material handling system upstream of the bulk bag filler can maintain a continuous rate of 30 tons per hour does not necessarily guarantee that bulk bags can be filled to match that rate.

As can be seen in the timing chart above, over half of the cycle time is consumed by tasks unassociated with actually getting the bulk solid product into the bag.

In our example there is only 55 seconds allowed to deposit 2,000 lb of product into the bulk bag. That means the required instantaneous bulk solid flow rate is roughly 130,000 lb per hour!

If the bulk bag filling machine performs weighing during this time, a 'dribble feed' task is required. That means that part of the 55 seconds alloted to filling the bulk bag with product is used to dribble the last, say, 50 lb of product into the bulk bag to maximize weighing accuracy.

Typically, for it to be effective, the dribble feed time is 10-15 seconds in duration. That leaves only 40 seconds to fill 1,950 lb into the bag. In that case the instantaneous fill rate is over 175,000 lb per hour!

Surge Capacity

As described in the above section, the bulk bag is actually being filled for only a portion of the total bag fill cycle time. The rest of the time - called overhead time - is taken up by other tasks.

During the overhead time bulk solid product cannot flow into the bag. However, since our bulk material handling system continuously feeds 60,000 lb per hour to the bulk bag filling system, the product conveyed during the overhead time must be stored above the bulk bag filler.

Typically, a surge hopper or storage vessel of some kind is used to hold the product conveyed to the bulk bag filler during the overhead time. Calculations can be made to determine the vessel volume necessary to hold the product - commonly called surge capacity.

Bulk Bag Filling System

The bulk bag filling machine must be designed to accomplish the tasks in the time alloted - while maintaining acceptable weighing accuracy and producing stable and safe bulk bags.

Features such as automatic loop release, automatically movable loop attachments, automatic bag removal, etc. are required.

However, the most critical consideration is that because each task duration is so short, each aspect of the bulk bag filler's design must be optimized to not only operate quickly, but to perform its function properly in so short a time. Weighing accuracy of +/- 1-2 lb and bags that have been filled to their maximum bulk density can be achieved when filling bulk bags in excess of 30 per hour. However, specialized designs are required.

Filled Bulk Bag Takeaway

Removing one filled bulk bag every two minutes from the bulk bag filling system is no easy task. Forklift traffic patterns must be considered as well as the round trip distance from the filling system to/from the warehouse storage point or loading dock.

Pushing The Envelope

Bulk bag filling rates in excess of 30 tons per hour can be achieved. Filling machines that perform weighing can be made to fill up to 35 bags per hour. Pre-weighing - weighing the product in a vessel above the filler and dropping the 'shot' into the bag as quickly as possible - can reduce the bulk bag filling cycle to the point where it is possible to produce over 40 bags per hour.

As can be seen there are many considerations that must be addressed when implementing a high speed bulk bag filling system. Careful work conducted in partnership with the bulk bag and bulk bag equipment vendors is a must to ensure success.

shipped without pallets. For example, export shipments of various products that travel via shipping containers are often shipped without any kind of bottom support. In North America, one of the resin industries converted from boxes to bulk bags now all domestic production of this type of resin is shipped in bulk bags without bottom support.

shipped without pallets. For example, export shipments of various products that travel via shipping containers are often shipped without any kind of bottom support. In North America, one of the resin industries converted from boxes to bulk bags now all domestic production of this type of resin is shipped in bulk bags without bottom support.