Topics: bulk bags, bulk bag unloader, bulk bag discharger, Bulk Bag Dischargers, dischargin bulk bags, discharger, unloader

Bulk Bag Weighing Accuracy - 4 Critical Success Factors

Topics: bulk bags, bulk bag filling, bulk bag accuracy, bulk bag fillers, bulk bag weighing, filling accuracy bulk bags, weighing accuracy bulk bags, weighing bulk bags

How much product are you giving away for free in you bulk bags?

Topics: bulk bag filler, bulk bag, bulk bags, bulk bag filling, bulk bag fillers, Bulk Material Handling, dry bulk material handling, dry bulk solid, overfilling bags, profit, profitability bulk bag filling, profitability bulk bags, overfilling, overfilling bulk bags

Handling Hazardous Ingredients in Bulk Bags

Topics: bulk bags, bulk bag fillers, bulk handling equipment, Bulk Material Handling, bulk material handling equipment, hazardous material

Sugar in Big Bags Not Small Bags: Excellent ROI

A major Caribbean beverage producer - juices, soft drinks, etc. - wanted to improve productivity related to sugar handling.

Their current process involved manually breaking 50 Kg bags at multiple locations. Not only was this labor intensive, but it was soon to be a bottleneck that would impede planned increases in production output.

Working with their primary sugar supplier, one of the largest sugar brokers in the region, and Control and Metering, the beverage company created a plan to achieve their productivity goals and increase the scale of their sugar handling to meet higher production rates by changing incoming sugar packaging to big bags and designing a new sugar batching system.

Big Bags versus Small Bags

Handling sugar required six operators continuously breaking and dumping 50 Kg bags at three locations.

Plus, the 50 Kg bags had to be unloaded from shipping containers one bag at a time and placed in storage manually. This also required multiple operators.

Converting to big bags would allow container unloading to be performed by one operator with a forklift.

Instead of six operators breaking bags at three locations, current production and planned growth for the next two years could be managed by one operator and two automated big bag batching stations.

Batching Sugar from Big Bags

The big bag sugar batching systems were designed to precisely convey sugar to syrup mixing tanks to produce standard brix syrup that would be pumped to all of the beverage production lines in the plant.

Each big bag batching system included a Control and Metering F60 monorail big bag discharger, an incline screw conveyor and an automated batch weighing control system.

discharger, an incline screw conveyor and an automated batch weighing control system.

Big bags would be moved to the production area and the single sugar batching operator would move individual big bags to each of the two big bag batching stations using a pallet truck. The big bag would then we rigged to a lifting frame and placed into the F60 big bag discharger using an integral hoist and trolley.

The operator would then safely open the big bag outlet spout within the F60 hopper to initiate sugar flow and, by pressing a single button on the control panel, start the batch.

The operator would then safely open the big bag outlet spout within the F60 hopper to initiate sugar flow and, by pressing a single button on the control panel, start the batch.

The automated batch weighing system would then control the conveying of sugar from the big bag to the syrup mixing tank according to the syrup recipe.

control the conveying of sugar from the big bag to the syrup mixing tank according to the syrup recipe.

Economic Benefit of Converting from Small Bags to Big Bags

The fully benefited labor rate at this location is $2.72 USD per hour. Even at this relatively low rate (compared to North America and elsewhere), first year labor savings were calculated to be $152,000 USD with second year savings of $196,000 USD based on increased production.

This resulted in a simple payback for the project of only 21 months. Clearly, the ROI on this project was very attractive!

For more information contact Don@ControlandMetering.com.

Topics: big bags, bulk bags, bulk bag unloading, bulk bag batching system, sugar, 50 Kg bags

High Speed Bulk Bag Filling - Preweighing Design Considerations

In the article "High Speed Bulk Bag Filling - Preweighing", preweigh bulk bag filling systems, capable of achieving filling rates up to 40 bulk bags per hour, were described:

"Pre-weighing refers to weighing the payload of product to be placed in a bulk bag in a separate bin or hopper above the bulk bag filling machine.

Doing so eliminates the time required to precisely weigh the product as it flows into the bulk bag on the filling machine. Rather, the pre-weighed 'shot' can be dropped into the bulk bag as quickly as it can be made to flow through the pre-weigh hopper outlet."

In this article critical design considerations will be discussed.

Product Conveying Balance

A preweigh bulk bagging system capable of filling 40 bulk bag per hour must be 'fed' by the upstream production process and the system that conveys product to the bagging location, at the same rate - product in must equal product out.

This can be accomplished in two ways.

Often, the production line will continuously convey product to a large silo (50+ tons capacity). The preweigh bulk bagging system is located underneath the silo and bulk bagging occurs either continuously, if production can keep up with the bulk bagging rate, or periodically when production has filled the silo to an appropriate level.

A less common arrangement is where the production line can continuously match the bagging rate and product is continuously conveyed to the bagging line where it is continuously filled into bulk bags.

Weighing

Designing the weighing sub-system is the most challenging aspect of implementing a preweigh bulk bagging system.

As was shown in the previous article, a 40 bag per hour system has a total cycle time of 90 seconds. Of that, 15 seconds is allocated to emptying the preweigh hopper (the vessel wherein the product shot is weighed) into the bulk bag. From the preweigh hopper's perspective, the remainder of the cycle time - 75 seconds - can be used to weigh the next shot.

Assuming a typical dribble feed duration of 15 seconds, the fast fill portion of the weighing cycle is 60 seconds.

Typically, 50 - 100 lb of the total shot weight is dribble filled. That means that, in the case of a 2,000 lb bag, 1,950 lb of product must be metered into the preweigh hopper in 60 seconds. This equates to a very high instantaneous flow rate of approximately 117,000 lb/hr.

Two key factors must be considered to maintain accurate and consistent weighments:

- Flow control. The device used to meter the product into the preweigh hopper must be properly selected.

- Flow rate. The rate at which the product flows into the preweigh hopper must be consistent from bag to bag.

There are a number of ways to design such a weighing system according to the desired weighing accuracy and capital budget.

Note that preweigh systems can be designed to consistently maintain accuracy of +/- 2 lb.

Bag Stability

The faster bulk bags are filled the less time is available for densification. Further, bag stability becomes more of a concern as the bulk bag filling rate increases.

Applications with bagging rates over 20 per hour must be carefully assessed to determine what amount of densification is required to produce safe and stable packages.

As the bagging rate approaches 25 bulk bags per hour and beyond, stability and densification become a major concern with almost any product - particularly if stacking the bulk bags is a requirement.

In a preweigh system capable of filling 40 bulk bags per hour, the filling machine must be carefully designed to ensure the filled bags are stable and safe.

In the next article we will look at when a preweigh bulk bagging system should be used.

Topics: bulk bag filler, bulk bag loading, bulk bag loader, bulk bag, bulk bags, pre-weighing, bulk bag filling, fibc, fibcs, bulk solids, pre-weigh, preweighing, high speed bulk bag filling

Maximum bulk bagging rates are achieved when using a pre-weigh system.

Pre-weighing refers to weighing the payload of product to be placed in a bulk bag in a separate bin or hopper above the bulk bag filling machine.

Doing so eliminates the time required to precisely weigh the product as it flows into the bulk bag on the filling machine. Rather, the pre-weighed 'shot' can be dropped into the bulk bag as quickly as it can be made to flow through the pre-weigh hopper outlet.

So, instead of a fast feed and dribble feed cycle with weighing conducted on the filler that, at its fastest consumes 50-55 seconds, a pre-weigh system can fill a bulk bag in approximately 15 seconds.

Removing 40 seconds from the bulk bag filling cycle time dramatically increases the bulk bagging rate.

Bulk Bag Filler vs. Pre-weighing

Let's examine the numbers in more detail:

| Task | Filler Weighing

(seconds) |

Pre-Weigh (seconds) |

| Rig bulk bag | 30 | 30 |

| Tare | 5 | 5 |

| Fast Fill | 40 | 15 |

| Dribble Fill | 15 | NA |

| Final densification | 15 | 25 |

| Remove filled bag | 15 | 15 |

| 120 seconds | 90 seconds |

Note that the Filler Weighing cycle time is only 120 seconds - that equates to 30 bags per hour.

That is a very high rate and is possible with many products using high speed bulk bag filling equipment. However, as can be seen, adding a pre-weigh system to this type of bulk bag filler increases the bagging rate considerably.

A 90 second cycle time means that a properly designed pre-weigh system is capable of filling 40 bulk bags per hour!

Also note that the final densification time has been increased. This compensates somewhat for the reduced amount of total densification time compared to the Filler Weighing cycle where the bag would be densified for most of the Fast Fill task.

In our next article we will dive into the design issues that must be considered to properly implement a bulk bag pre-weigh system.

Topics: bulk bag filler, bulk bag, bulk bag handling, bulk bags, pre-weighing, bulk bag filling, fibc, fibcs, pre-weigh, preweighing, high speed bulk bag filling

Last week I had dialogue with a potential customer who was stumped with a bulk bag problem. The solution had nothing to do with bulk bag handling equipment; rather it had everything to do with the flexibility of bulk bags themselves.

This customer was faced with having to fill bulk bags with a sludge like material that contained over 20% moisture. Needless to say, it easily bridged and ratholed.

Specifically, the customer's system was being designed to mechanically convey the product to a small surge hopper, which would in turn empty into a bulk bag.

The customer was searching for a way to ensure that the product would flow easily from the surge hopper into the bulk bag. However, they had been unable to find a suitable solution to getting the sludge through the bulk bag inlet spout sized at the typical 14" diameter.

The answer required a paradigm shift. That was: bulk bags do not have to have a spouted top.

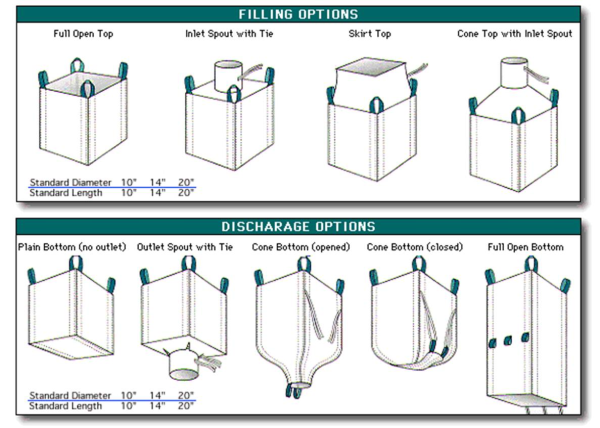

As can be seen in the following diagram, bulk bags can be manufactured with many different top and bottom configurations.

In the case of this application the solution was to use the 'skirt top' design shown above - also commonly known as a duffle top bag.

This allowed the customer to design the surge hopper with an outlet large enough to prevent bridging and ratholing while still being able to get the product into the bag.

All they had to do was open the duffle top to completely expose the inside of the bulk bag and let the sludge fall from the large opening in the bottom of the surge hopper.

Because the product was so heavily moisture laden dusting was not an issue. Therefore, there was no need to have the bulk bag inlet sealed to the surge hopper outlet.

Plus, the duffle top allows the bag top to be tied and closed securely preventing comtamination of the product and spills.

The customer was able to simply, easily and inexpensively solve their problem once they learned that - true to their name - Flexible Intermediate Bulk Containers or bulk bags can be designed to suit almost any bulk solids handling task - flexible indeed!

Topics: bulk bag filler, bulk bag design, bulk bag, bulk bag handling, bulk bags, bulk bag filling, fibc, fibcs, bulk solids, duffle top, skirt top

Bulk Bag Weighing Accuracy - 4 Critical Success Factors

Bulk bags can and should be weighed to within +/- 2 to 5 lbs accuracy - at any bagging rate with any product.

Following are the four critical factors that must be considered to achieve acceptable bulk bag weighing accuracy:

- Consistent product flow. Any batch weighing application's accuracy increases as the consistency of the product flow rate increases. This refers to the flow rate during a batch and from batch to batch. Bulk bag fillers typically have a weighing algorithm that includes an "in-flight offsett" program that 'learns' when to stop product flow ahead of reaching the weight target to compensate for product that is falling between the metering device and the bulk bag. The more consistent the flow the better the algorithm is able to fine tune the system.

- Metering device. Weighing accuracy is critically dependent on how well suited the metering device is to the application. A simple, two position gate valve may provide adequate accuracy when filling bulk bags with reasonably low bulk density product at a slow rate. However, when filling a high bulk density product at a high rate a conveyor/feeder may be required to achieve the desired accuracy. Note that the ultimate accuracy of a positive displacement type metering device (e.g. screw conveyor, screw feeder, rotary airlock, etc.) is limited to +/- the weight of product in one flight or pocket. Therefore, high bagging rate applications require great care in selecting the best metering system: a conveyor sized to provide a high flow rate necessary to achieve the desired bagging rate may not be able to produce adequate weighing accuracy because it is too large In that case, a different metering device, a second dribble feed device or a surge hopper with fast acting gate valve may be required.

- Dead load. The weight that the weighing system sees before product is added to the bulk bag is called the dead load. Gross weighing systems - those that weigh the entire bulk bag filler along with the product in the bag - can see a dead load of up to 2,000+ lb depending on the filler and its configuration. Bulk baggers that use hang weighing see a dead load equal to a few hundred pounds. This means the hang weighing filler can use smaller load cells or that the portion of the load cell span taken up by the dead load is much smaller. Either way, higher weighing resolution and more accurate weighing is the result.

- Weighing system minutiae. When filling bulk bags the specific type of load cell, controller/PLC resolution and scan time and the like are really not significant factors in achieving weighing accuracy. In my experience any weight controller and PLC implimentation has more than enough resolution to achieve the desired bulk bag weighing accuracy.

Topics: bulk bag filler, bulk bag loader, bulk bag, bulk bags, bulk bag filling, weighing accuracy, weight controller

Training - Critical To Bulk Bag Discharging Success

Topics: dust containment, operator training, bulk bag, bulk bag discharging, bulk bag handling, bulk bags, bulk bag unloader, bulk bag unloading, fibc, fibcs, bulk bag discharger