This article was written by Dan Schnaars, President of Ameriglobe LLC, one of North America's premier FIBC manufacturers.

When to Use Liners vs. Laminated Fabric vs. Fabric for your Bulk Bags

When you are in the process of designing your bulk bag packaging specifications, one of the key issues to consider is the kind of environmental protection the bag must provide to your product.

The best answer for you can sometimes be quite detailed. Here we will consider the three basic types of protection.

Uncoated or Breathable Fabric Bulk Bags.

Bulk bags are made of woven polypropylene. While the weaving makes a fabric that appears quite solid, it is, in fact, breathable. Air and ambient moisture pass quite easily through plain fabric. Dusty products contained within can ‘dust' through the fabric and/or the seams of the bag. For the majority of applications, breathable or plain fabric does not provide enough containment. Any product contained in a breathable fabric bag will likely reach ambient humidity levels within a few days.

But, some products such as soy bean seeds or peanuts require a breathable container. The airflow retards germination and mold and is, therefore, a necessary feature. Many minerals travel in breathable fabric bags due to cost. The mineral products often have a low cost per ton and the packaging cost is quite a significant factor in the final product cost. Coating the fabric does add cost to any fabric.

Laminated (coated) Fabric Bulk Bags

The most common method of environmental protection for your bulk bagged product is to use a bag that has a thin layer of film laminated to the inside of the bag. This lamination eliminates most of the air flow through the bag. Most products travel well in this type of bulk bag. Dusty products do not pass through the lamination and dust from the outside does not enter the bag through the weave. Ambient humidity transfer is greatly limited by the lack of air flow as well. If small amounts of sifting are not an issue and small amounts of contamination are not an issue, then this bag is most often the right choice.

Lined Bulk Bags

The need for extreme cleanliness, moisture control, or oxygen flow is what generally dictates the need for liners.

Contamination Issue - Bulk bags are made from a manual sewing process. The fabric itself is often charged with static electricity that causes small pieces of sewing thread to cling to it. Some companies are vacuuming the insides of the bag and working in clean environments, but this is only a reduction of the opportunity and amount of contamination. Over the course of time, a loose thread or two will occur.

Sifting issue - In the sewing process, a needle punctures the fabric and carries a thread through the hole with it. In order to do this the needle has to be bigger than the thread it leaves behind. Powders will often pass through this extra space. To reduce this, bulk bag manufacturers offer to add ‘sift-proofing' materials to the seams. Again, while this greatly reduces the amount of product that can sift through the seams, it can never be 100%. If it were, then bulk bags made in this way would be able to hold water and not a single one can do this.

Only the proper use of a liner can ‘100% guarantee' that there will be NO contamination in your product.

Moisture control - If sifting cannot be prevented, then you can easily see why strong moisture control cannot be attained without a liner as well. The selection of the specific liner is just as important as the selection to have any liner at all.

Most applications will use a 2 to 3 mil polyethylene liner. This liner will work for almost all food applications, general moisture control, all sifting and contamination issues.

Specialized liners can be used when there is an absolute and special need. For absolute moisture control, a liner with foil laminated to it can be used. Liners with special gas transmission rates are selected when odors need to be contained or oxygen must be kept out.

Hazardous materials almost always require the use of a liner.

Liner attachments - The final piece to this discussion would be the connection between the liner and the bag itself. Although many companies simply put the liner into the bag with no connection, this will often create problems for the end user during the discharge process.

If the liner is unattached, it simply falls out with the product and becomes a contaminate in the receiving hopper. Liners should be physically attached to the bag so that it will stay in the bag as the product leaves the bag.

There are three methods for attachment; sewing, tape tabbing and gluing. Different products need different strengths of holding power.

Some products like pellets will flow very easily from the bag. It takes very little attachment support to hold the liner within the bag. In this case, any of the attachment methods will work well.

Other products tend to clump together such as powders. These products can grab the liner more intensely. It takes much more holding power to keep the liner attached to the bag.

While opinions may vary, the method of attachment that involves the greatest number of square inches of the liner for its strength is a good gluing method. Done well, this method can generate the most holding power possible for the most difficult applications.

Whatever your need, when you are designing a bulk bag package, involve your bulk bag supplier in the decisions. They should be able to recommend the best product protection for your application.

-Dan Schnaars, President Ameriglobe LLC

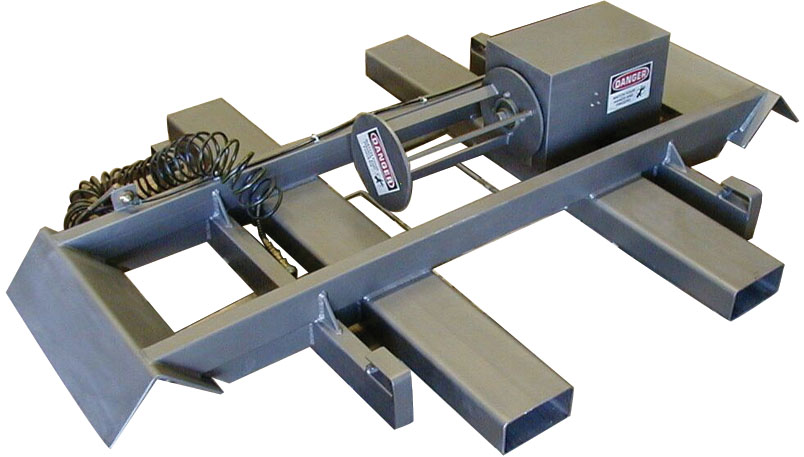

Do you receive ingredient in bulk bags with loose liners? Do you have problems getting the ingredient to flow from the bulk bag? Here's some tips on how to overcome bulk bag discharging flow problems.

Do you receive ingredient in bulk bags with loose liners? Do you have problems getting the ingredient to flow from the bulk bag? Here's some tips on how to overcome bulk bag discharging flow problems.