Do you receive ingredient in bulk bags with loose liners? Do you have problems getting the ingredient to flow from the bulk bag? Here's some tips on how to overcome bulk bag discharging flow problems.

Do you receive ingredient in bulk bags with loose liners? Do you have problems getting the ingredient to flow from the bulk bag? Here's some tips on how to overcome bulk bag discharging flow problems.

Focus on how the bags are filled.

Flow problems often are the result of the bulk bag liner not being inflated prior to filling. If this crucial step is not taken, the liner can fold over itself in the bottom of the bag. If that happens and a ton of ingredient is filled into the bag on top of the folds, flow problems are sure to occur.

The only way to prevent this is to properly inflate the liner just prior to filling so that it takes the shape of the bulk bag without folding over on itself. Talk to your supplier or, if you fill bulk bags for in-house or intra-company use, take a close look at your bulk bag filling equipment and standard operating procedures.Optmize liner handling during discharge.

Liner tensioners are devices that wind up loose liners during discharge to prevent them from 'growing' too far out of the bottom of the bulk bag and becoming entangled in downstream equipment. They also improve product flow and ensure that all of the ingredient is discharged from the liner thereby providing 100% yield.

Using one of a number of different styles of liner tensioner can prevent flow problems from bulk bags with loose liners.

- Hold in place. The simplest type of liner tensioner simply holds the liner in place to prevent it from completely exiting the bottom of the bag during discharge. Make sure that there is sufficient space between the bottom of the bag and the downstream equipment so that when the liner grows out of the bag during dicsharger it doesn't become entangled in downstream equipment. Also note that this style tensioner does not pull up on the liner and therefore does not do an effective job of ensuring complete discharge.

- Partial wind up. A pneumatically actuated tensioner winds up a predetermined amount of the liner during discharge - say 24" - 36". This reduces or eliminates liner growth out of the bag bottom and ensures complete discharge.

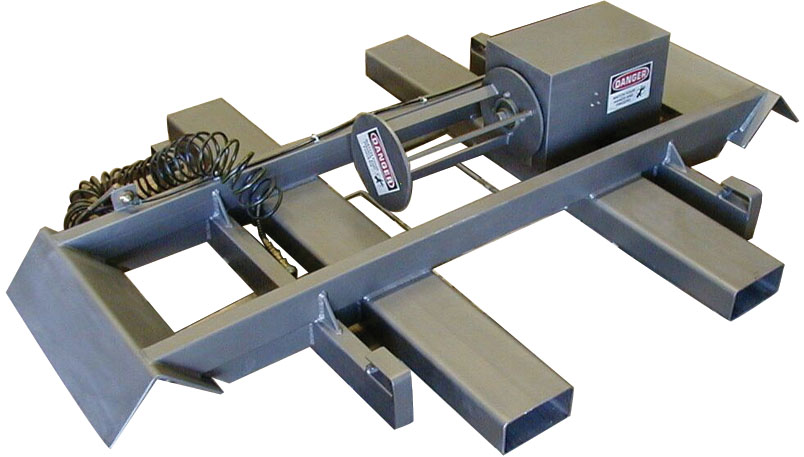

- Complete wind up (see photo above). If you use a discharger that clamps the liner outlet you must use a tensioner that continuously winds the liner. Otherwise, the liner will gather at the clamp and almost always prohibit ingredient flow. This type of discharger and tensioner are typically used when dust containment is critical.