Recently, we engaged with a customer that a few years ago had spent over $2 million with another vendor on an 18 station, automated bulk bag batching system. Depending on the recipe some or all of the 18 different ingredients are simultaneously metered onto a common belt conveyor for transfer to one of two mixers. Each station dispenses its ingredient in specific batch weights according to the recipe.

Recently, we engaged with a customer that a few years ago had spent over $2 million with another vendor on an 18 station, automated bulk bag batching system. Depending on the recipe some or all of the 18 different ingredients are simultaneously metered onto a common belt conveyor for transfer to one of two mixers. Each station dispenses its ingredient in specific batch weights according to the recipe.

Unfortunately, the system doesn't work.

Individual ingredient batch weights are inaccurate and vary both above and below the weight setpoint and the variations are random. Therefore, the total recipe weights are inconsistent and are randomly under or over weight.

As a result, they have had to go back to adding most of the ingrdients by hand and use the automated system for only four or five ingredients.

The customer asked Control and Metering if we had any ideas that might help them. Based on a very brief overview of the system and how it operates we identified two key factors that we believe may be root causes of the weighing problem. These factors are critical to achieving success with any batching system.

- Dry bulk solid metering device selection. The 18 ingredients vary dramatically in their bulk density, particle size distribution and flow characteristics. Each station must be optimized for its ingredient so that the bulk bag discharger maintains a steady flood feed condition to the metering device and so that the metering device is properly selected to maintain a constant - and therefore accurate - feed rate when it is dispensing its batch. In this case, vibratory feeders were supplied at every station, which appear to be inneffective with many of the ingredients.

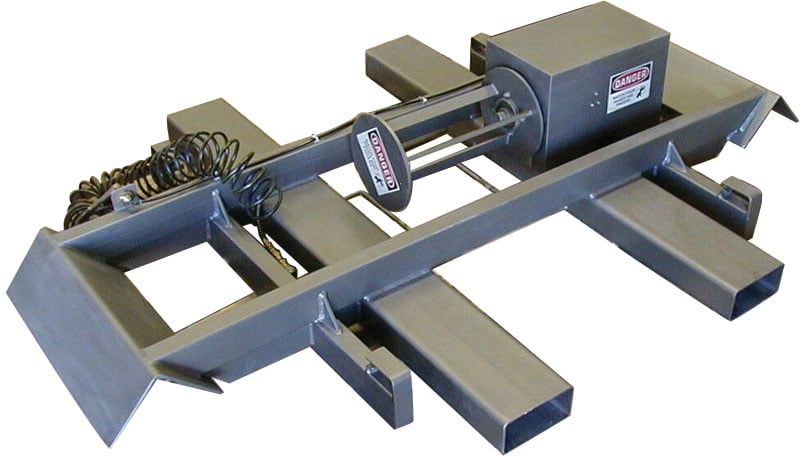

- Batch weighing structure integrity. Each of the 18 bulk bag batching stations are constructed of 3" steel tubing and the metering devices - vibratory feeders - are suspended below each frame on chains. Load cells are located under each of the bulk bag discharger legs. We suspect that the overal structure lacks integrity and may well exhibit hysteresis - the frame subtly shifts each batch run or series of batch runs and the weighing system physically alters its orientation - perhaps by only millimeters - between batches. Further, it may be that frame flexing occurs during batch operation. Both of these phenomenon, if they are occuring, would lead to random batch inaccuracies. The weigh frame or weighed structure must be designed to avoid frame flexing and deformation so that the weighing system remains structurally rigid from batch to batch.

As was pointed out in an earlier blog post "

As was pointed out in an earlier blog post " Do you receive ingredient in bulk bags with loose liners? Do you have problems getting the ingredient to flow from the bulk bag? Here's some tips on how to overcome bulk bag discharging flow problems.

Do you receive ingredient in bulk bags with loose liners? Do you have problems getting the ingredient to flow from the bulk bag? Here's some tips on how to overcome bulk bag discharging flow problems.